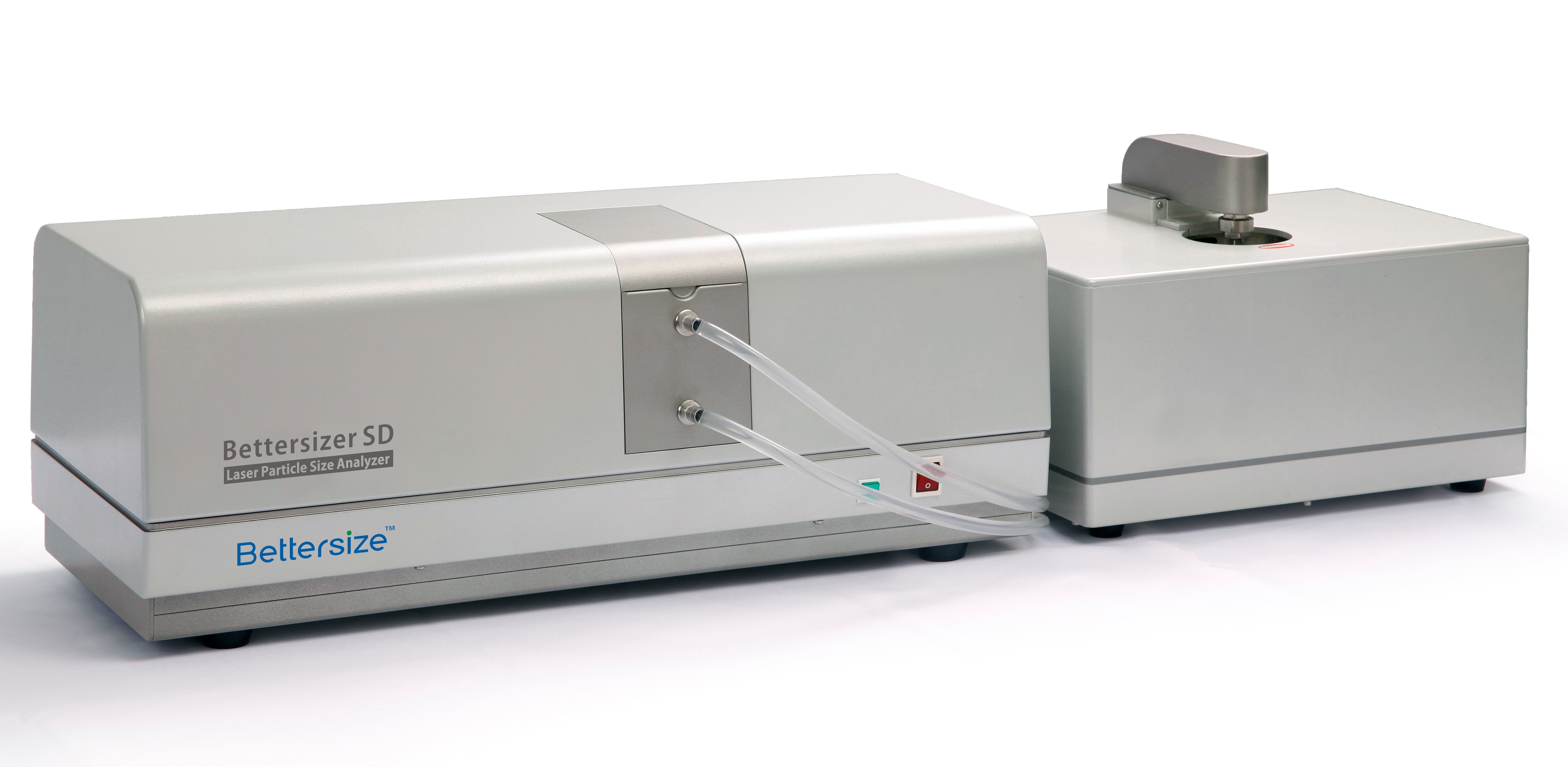

Introduction of Bettersizer SD (Wet):

Bettersizer SD particle size analyzer is an intelligence dry and liquid dual-purpose particle size analyzer. Dry dispersing system adopts Venturi dispersing effect, through the measures of shear, inertia, collision, etc. to ensure that the powders are in complete dispersing state when pass test window. It adopts aerodynamics technology to prevent the lens from pollution and has outstanding characteristics of accuracy and good reliability, good repeatability, easy operation, fast test speed, etc. It is high performance dry particle size test instrument, and especially suits pharmaceutical, cement, magnetic materials enterprises and the laboratories of colleges and universities as well as research institutes to use.

Repeatability:

Excellent repeatability is achieved thanks to:

- Laser, detector and signal transmission system are stable and reliable.

- Consistent and effective dispersing system.

- Automatic alignment keeps the instrument always in optimum condition.

- Sampling rate up to 3500 times/second ensures outstanding repeatability

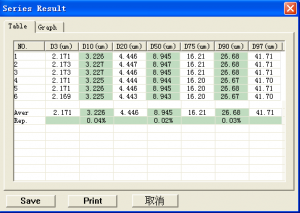

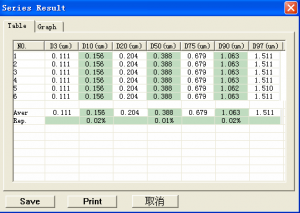

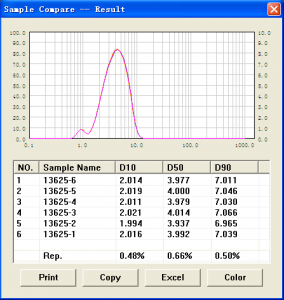

Repeatability verification:

a) Repeatability of a serial test for same samples

b) Repeatability of re-sampling tests

Accuracy:

Excellent accuracy is achieved thanks to:

- The use of a dual lenses optical system (DLOS) invented by Bettersize, it improves the precision of the analysis compared to single lenses systems.

- The use of 84 detectors plus high performance software, provides excellent resolution regardless the sample has a single modal or multimodal distribution.

- Complete sample preparation system including circulation, ultrasonic dispersing, stirring, auto water supply and auto cleaning.

- Use of size standard to verify the accuracy of the results.

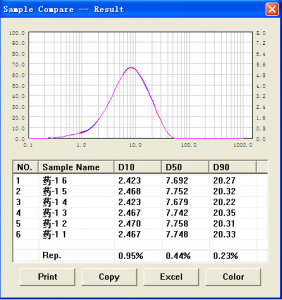

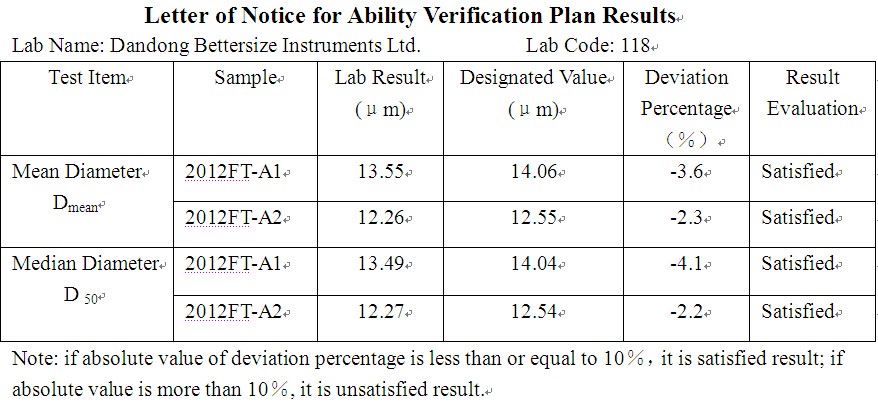

Verifications of accuracy:

a) Accuracy which approved by China National Accreditation: Satisfactory

b) Compare with test results of overseas advanced laser particle size analyzer: Good consistency.

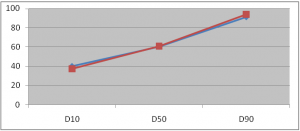

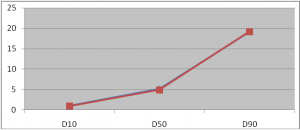

b) Compare with test results of overseas advanced laser particle size analyzer: Good consistency.

| Caco3 | D10 | D50 | D90 |

| Other brand | 0.981 | 5.144 | 19.122 |

| Bettersizer SD | 0.943 | 4.936 | 19.22 |

| Silicon Dioxide | D10 | D50 | D90 |

| Other brand | 39.89 | 60.499 | 91.083 |

| Bettersizer SD | 37.08 | 60.64 | 93.83 |

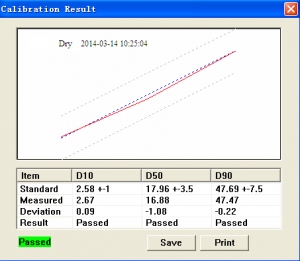

c) Use Bettersize standard sample to verify accuracy and test value is identical with standard value.

Reliable performance and easy operation

Reasons for low failure rate:

- Use of high quality components.

- Use of high quality components.

- Components are inspected and recorded for traceability. A 48-hour failure test before instruments leaves the factory.

- Use of advanced technologies such as dry burning-resistant ultrasonic, auto alignment, dew-point temperature detecting and others

- Comply with CE, FDA 21 CFR Part 11 and ISO 9001-2008 certification.

Easy operation:

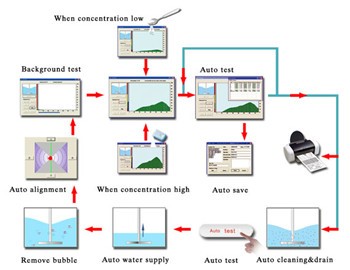

Intelligent standard operation procedure (SOP) design: Just add sample, system can complete the operations such as water supply, dispersing, circulation, concentration adjustment, test, drainage, cleaning, print, storage, etc. If the concentration is high, the system will dilute automatically. If the concentration is low, the system will show “add the sample”, to guarantee that the concentration always keeps optimum status. The direct effect of full-automation is not just for easy operation. More importantly, it reduces the errors caused by human factors and improves test precision.

Unique technology and reliable quality

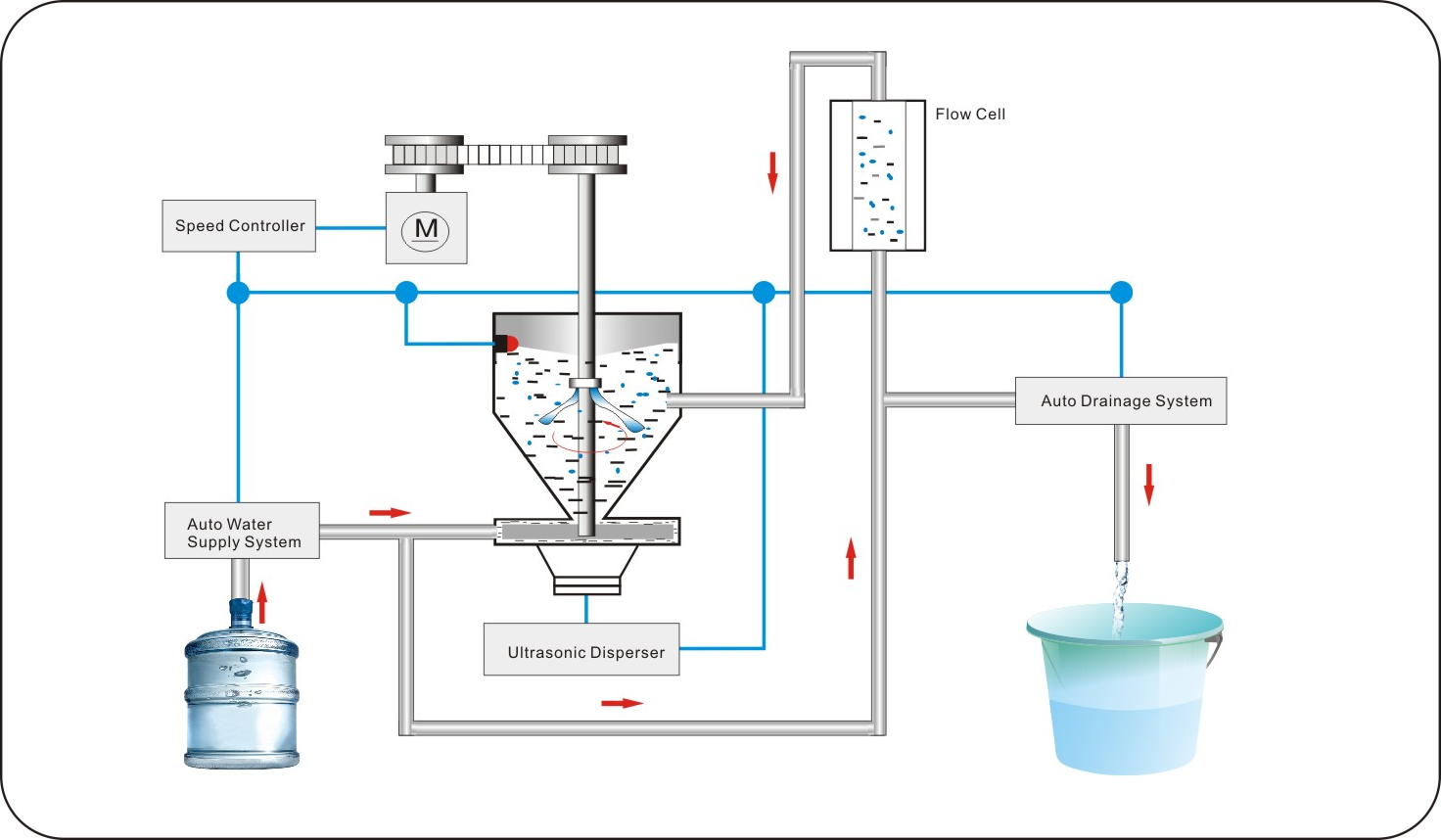

Reliable circulating and dispersing system:

BT-801 automatic liquid circulating and dispersing system which matches Bettersizer SD included anti-dry ultrasonic disperser,centrifual circulating pump, auto water supply system, auto drianage system and auto overflow system. It applies to all kinds of samples and ensures that sample can be dispersed completely. The accurancy and repeatability of the test is guaranteed.

Unique conversion technology between dry and liquid: The instrument provides BT-801 wet feeding system and BT-901 feeding system. Just change feeding system and set corresponding software, then conversion between dry and wet can be completed quickly.

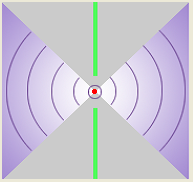

Auto alignment technology:

Auto alignment system individually invented by Bettersize is composed of stepping motor, precise guide rail, subdivision controller and software system. Its function is to let the center point of photodetector which is installed on it always keep optimum location, to guarantee accuracy and precision of the measurement.

Auto alignment system individually invented by Bettersize is composed of stepping motor, precise guide rail, subdivision controller and software system. Its function is to let the center point of photodetector which is installed on it always keep optimum location, to guarantee accuracy and precision of the measurement.

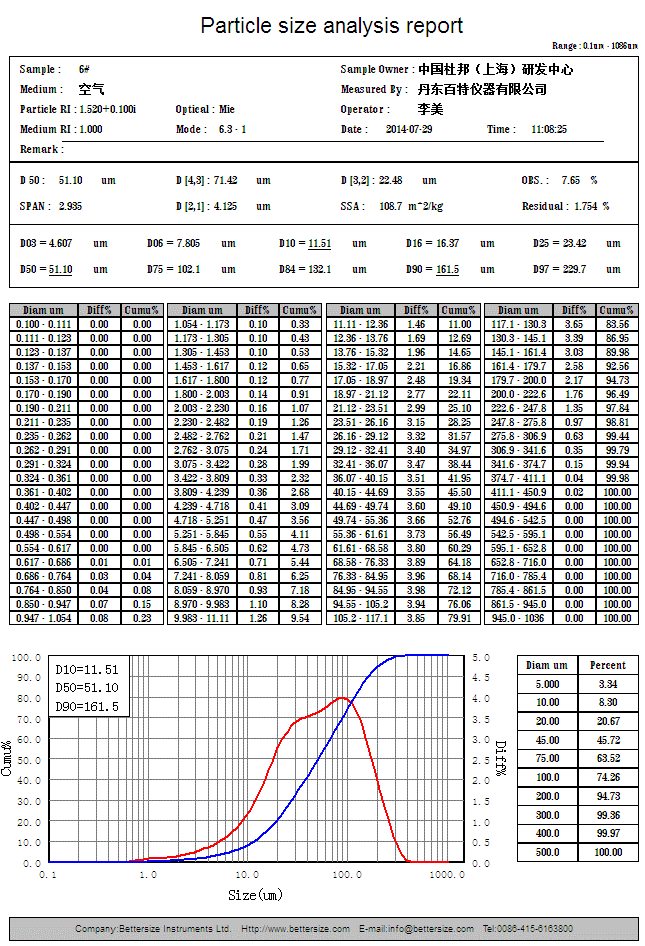

Software system:

The functions of the software system for Bettersizer SD are very powerful. Herein, only list the conversion of report format for example. Just click Excel, PDF, Copy and Export button, the conversion of report format can be realized. It is convenient for communication such as email and so on.

Examples of report type (more than 14 types are optional in total)

Specification

| Testing parameter | Material |

| Particle size distribution | Suspension, emulsion, dry powder |

| General | Bettersizer SD |

| Theory | Laser diffraction |

| Analysis theory | Mie and Fraunhofer |

| Testing speed | 3kHz |

| Typical measurement time | ≤10 second |

| Size | |

| Size range | 0.1 - 1000um |

| Number of size classes | More than 100 customized grades |

| Accuracy | Wet ≤1% (GBRM D50) Dry ≤3%(GBRM D50) |

| Repeatability | Wet ≤1% (GBRM D50) Dry ≤3%(GBRM D50) |

| Resolution ratio | Single peak, double peak, multi-peak |

| Optics | |

| Red light | Max. 3mW, Semiconductor optical fiber laser, 635nm |

| Lens arrangement | Single lens |

| Lens design | F-Theta Lenses |

| Effective focal length | 223mm |

| Detector | |

| Arrangement | Log-spaced array |

| Quantity | 84 pieces (forward, sideway) |

| Light path adjustment | Intelligent automatic alignment |

| Sample dispersion system | |

| Dispersion type | Wet & Dry |

| Dispersion system | Ultrasound 50W, 38 KHz

Dry burning-resistant protection system |

| Water circulation | Centrifugal pump, 500 -2500 ml/min,

auto water intake and rinsing |

| Water capacity | 600 ml |

| Dispersion system available | Solvent compatible system |

| Air flowrate | 400-6000L/min |

| Air compressor | Gas container ≥ 60L , Pressure ≤ 8bar |

| Vacuum cleaner | Wet dust collector or bag filter |

| Air filter | 3 um, 0.3 um, 0.01 um |

| Software | |

| 21 CFR Part 11 | Enable |

| SOP Designer | Enable |

| Report | More then 14 formats report |

| Auto test | Enable |

| Data export | EXCEL, PDF,WORD, JPG and etc. |

| System compliance | |

| Laser class | Class I laser product |

| System | |

| Supply voltage | 220VAC |

| Dimension | 720mm x 300mm x 280mm (L x W x H) |

| Weight | 26kg |

| Computer specification | |

| Computer interface | At least a USB2.0 port required |

| Operation system | Windows XP, Windows 7,8 or 10 |

| Hardware specification | Intel Core I5, 4GB RAM, 250GB HD |