Surface Area and Porosity Instrument

Analytical Versatility/ High Throughput/

Small Footprint

The TriStar II Plus is a an automated, three-station, surface area and porosity analyzer that delivers excellent performance and speed of analysis. With three available analysis ports, the TriStar II Plus provides high sample through-put and advanced data analysis features to the user. The unique stainless steel analysis manifold is corrosive resistant and designed for highly accurate gas management for confident and repeatable results.

Advanced Hardware and Software Features

-

- The unique stainless steel analysis manifold is corrosive resistant and designed for highlyaccurate gas management

-

- Improved Dewar design provides more than 40 hours of continuous temperature control

-

- Intuitive MicroActive software gives the user the ability to interactively evaluate isotherm data and reduces the time required to obtain surface area and porosity results

-

- User-defined reporting options allow direct modeling

-

- Powerful Python scripting language allows users to develop extensions to the standard report library available within the TriStar II Plus software application

-

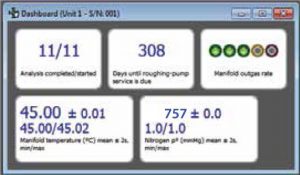

- An innovative dashboard monitors and provides convenient access to real-time instrument performance indicators and maintenance scheduling information

- Capable of utilizing two isotherms (CO2 and N2) for calculating pore size diameter via NLDFT for micropore analyses of carbons

Data Reduction Benefits

-

- Interaction with adsorption data is direct. By simply moving the calculation bars, the user is immediately updated with new textual properties. One-click access to important parameters allows the user to focus on the result rather than the parameters

-

- Interactive data manipulation minimizes the use of dialog boxes and tunneling of dialogs to specify calculation parameters. This allows the user to accurately and efficiently determine surface area and porosity of their materials

-

- Improved ability to overlay files (up to 25) including mercury intrusion data with a file add and subtract feature

-

- User selectable data ranges through the graphic interface allows direct modeling for BET, t-Plot, Langmuir, DFT interpretation, and much more

-

- Report Options editor allows the user to define up to five reports with on-screen previews. Each report has the ability to possess multiple summary, tabular, and graphical information panes

Low Surface Area Measurement Option

- A Krypton Option can extend surface area measurements to as low as 0.001 m2/g.

Enhanced Software Capabilities & Instrument Monitoring

MicroActive for TriStar II Plus Software

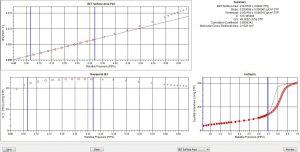

The intuitive MicroActive for TriStar II Plus software gives the user the ability to interactively evaluate isotherm data and reduce the time required to obtain surface area and porosity results. It is not necessary to generate reports to view results.

Calculations, such as the BET surface area transform plot, can be easily generated and adjusted. The selection bars allow for a range of data points to be quickly and easily selected. As a result, the summary of values derived from the calculations is instantly updated. Within the calculation window(s), the range of data used can be further refined.

Python Programming Language Included

The Python programming language has been incorporated into the TriStar II Plus software. This powerful scripting language allows users to develop extensions to the standard report library available within the TriStar II Plus application.

New isotherm models or calculations are easily added to the report system. The Python interface to MicroActive allows users to customize their reports and extend the utility of MicroActive.

New isotherm models or calculations are easily added to the report system. The Python interface to MicroActive allows users to customize their reports and extend the utility of MicroActive.

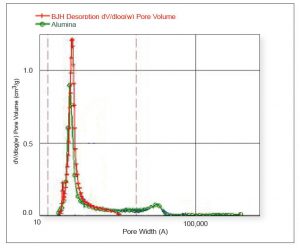

Gas Adsorption and Mercury Intrusion Overlay Capability

MicroActive for the TriStar II Plus software also includes a powerful utility that allows the user to overlay a mercury porosimetry pore size distribution with a pore size distribution calculated from gas adsorption isotherms. This new import function allows users to rapidly view micropore, mesopore, and macropore distributions in one easy-to-use application.

TriStar II Plus System Monitor

With a single click the TriStar II Plus provides a powerful suite of information that allows the user to maintain the instrument in peak operating condition with real-time analysis views.

Reporting Functions

Available tabular and Graphical Reports:

- Single and multipoint BET surface area

- Total pore volume

- Langmuir surface area and Isotherm reports

- t-Plot

- Harkins and Jura Thickness Equation

- Halsey Thickness Equation

- Carbon STSA

- Broekhoff-de Boer

- Kruk-Jaroniec-Sayari

- BJH adsorption and desorption

- Standard

- Kruk-Jaroniec-Sayari correction

- Dollimore-Heal adsorption and desorption

- Mesopore

- Volume and area distributions by pore size

- MP-Method

- HK

- Saito-Foley

- Chang-Yang

- DFT pore size

- DFT surface energy

- Summary Report

- SPC reports

- Validation reports

The Dual DFT

Extended Pore Range Analysis

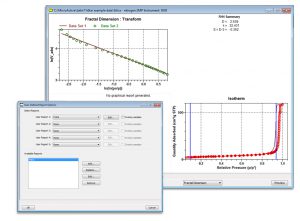

The Dual DFT NLDFT model allows the user to combine the information gathered from nitrogen and carbon dioxide isotherms to deliver a full pore size distribution on materials (such as carbon slit pores) where pores of molecular sizes are present. The range of pore size analysis in this method is extended to smaller pore sizes compared to the standard nitrogen analysis. This is due to the fact that CO2 can access some very small micropores that are not accessible to N2 at cryogenic temperatures due to size restrictions, connectivity problems, or extremely slow diffusion.

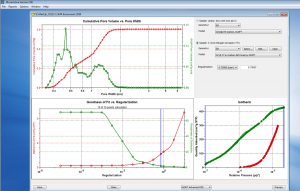

This advanced NLDFT method allows users to determine the pore size distribution of their sample using two isotherms. In this example CO2 adsorption (red) at 273 K and nitrogen adsorption (green) at 77 K are used to calculate a single pore size distribution. Users do not have to cut and paste distributions from CO2 and nitrogen - a single distribution is determined using both isotherms.

This advanced NLDFT method allows users to determine the pore size distribution of their sample using two isotherms. In this example CO2 adsorption (red) at 273 K and nitrogen adsorption (green) at 77 K are used to calculate a single pore size distribution. Users do not have to cut and paste distributions from CO2 and nitrogen - a single distribution is determined using both isotherms.

External Sample Preparation Devices

Micromeritics’ sample preparation devices prepare batches of samples for surface area and pore volume analysis. They combine flowing gas and/or vacuum with heat to remove atmospheric contaminants, such as water vapor and adsorbed gas, from the surface and pores of the sample.

The FlowPrep™ 060 applies both heat and a stream of inert gas to the sample for removal of adsorbed contaminants from the surface and pores. With six degassing stations, this sample preparation unit lets you choose the temperature, gas, and flow rate.

The FlowPrep™ 060 applies both heat and a stream of inert gas to the sample for removal of adsorbed contaminants from the surface and pores. With six degassing stations, this sample preparation unit lets you choose the temperature, gas, and flow rate.

The VacPrep™ 061 offers two methods for removing adsorbed contaminants. In addition to flowing gas, this sample preparation unit provides vacuum to prepare samples by heating and evacuation.

The SmartPrep™ 065 applies a stream of flowing gas over the sample at elevated temperatures to remove adsorbed contaminants. Temperature, ramp rates, and soak times of each sample are individually controlled on the six degas- sing stations by a computer.

The Smart VacPrep™ 067 is an advanced six-port system that utilizes vacuum to prepare samples by heating and evacuation. Each of the ports may be operated ind ependently. Samples may be added or removed from degas ports without disturbing the treatment of other samples undergoing preparation. Degassing automatically terminates when the samples have completed all programmed steps.

ependently. Samples may be added or removed from degas ports without disturbing the treatment of other samples undergoing preparation. Degassing automatically terminates when the samples have completed all programmed steps.