Introduction of BeVision S1:

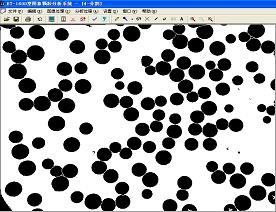

BeVision S1 Image Particle Analysis System includes optical microscope, digital CCD camera, image processing and analysis software, computer, printer, etc. It combines traditional microscope measuring method and modern image processing technology. The basic work procedure is that it shoots images by special digital camera; transfers particle images to the computer by USB data transmission; process and analyze the images by special particle image analysis software; output analysis results by displayer and printer. The system has characteristics of intuition, accuracy, wide measuring range, automatic identification, automatic counting, automatic calibration, etc., not only can be used to observe particle shape, but also can obtain particle size distribution, average L/D ratio and L/D ratio distribution, and provides a new particle size test method for the fields of scientific research and production.

Application Fields of BeVision S1:

Particle shape observation, particle size analysis, large particles monitoring

(1) Abrasive: silicon carbide, corundum, garnet, etc.

(2) Battery material: Spherical graphite powder, etc.

(3) Metal powder: spherical aluminum powder, lead-tin alloy powder, other atomized metal powders, etc.

(4) Nom-metallic powder: Such as glass beam, polystyrene, etc.

(5) Acicular powder: Such as wollastonite, etc.

(6) Biological agent: cell, etc.

(7) Food: Such as milk, flour, etc.

(8) Others: Such scientific research, teaching, etc.

Test Principle

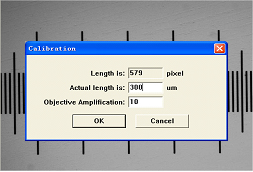

(1) Calibration method: Use special scale for microscope to calibrate the size for each pixel, and then measure the size of the particle in micron according to the pixel number of the area of each particle image.

(2) Test principle: Through counting particle number and the pixel number of each particle to calculate equivalent circle area and equivalent sphere volume of each particle, so as to obtain the diameter of equivalent circle area , diameter of equivalent sphere volume , L/D ratio, etc. For convenient operation, a measurement unit for BeVision S1 image particle analyzer is 100 pixels. The following table is corresponding particle size to 100 pixels for different objective amplification times:

| No. | Objective Magnification | Pixel | Particle Size(μm) | Remark |

| 1 | 4X | 100 | 250 | Corresponding particle size to 100 pixels is subject to calibration value. |

| 2 | 10X | 100 | 100 | |

| 3 | 40X | 100 | 25 | |

| 4 | 100X | 100 | 10 |

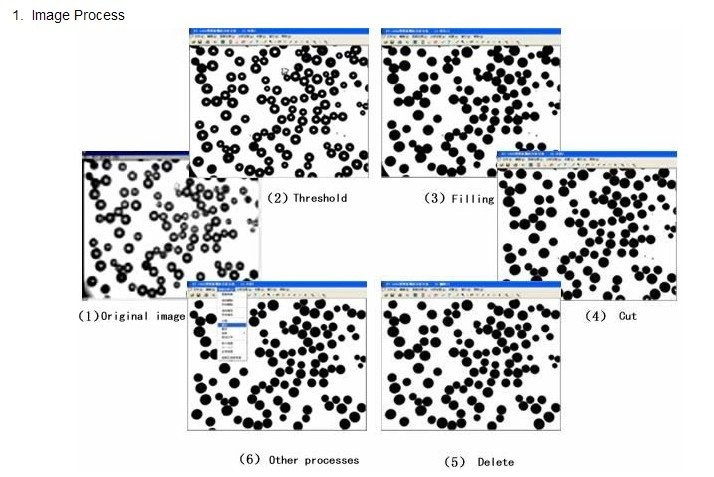

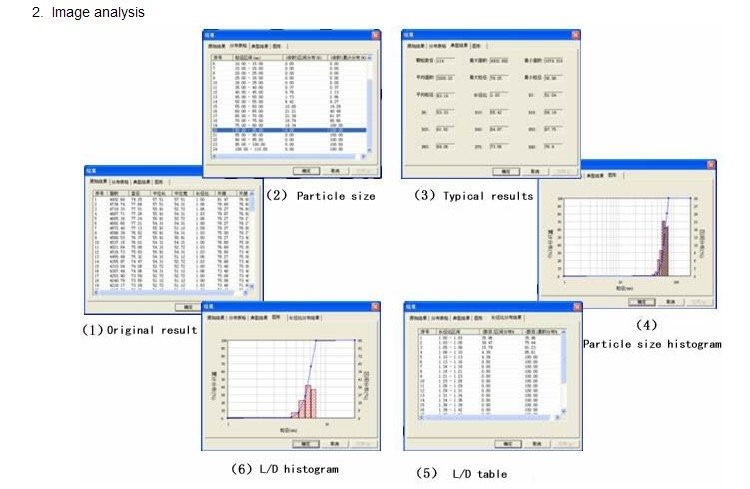

Examples for Software Functions

(1) Powerful image processing function: All managements are completed by this software and no need to use other image processing software.

(2) Image analysis: obtain particle size distribution, L/D ratio and its distribution, circularity and its distribution, the largest particle, etc

Reliable performance and easy operation

Reliable performance is achieved thanks to:

- Use of high quality components.

- Use of high quality components.

- Components are inspected and recorded for traceability. A 48-hour failure test before instruments leaves the factory.

- Use of advanced technologies such as dry burning-resistant ultrasonic, auto alignment, dew-point temperature detecting and others

- Comply with CE, FDA 21 CFR Part 11 and ISO 9001-2008 certification

System features:

(1) Calibration: BeVision S1 image particle analysis system can calibrate the real size of the particle accurately through the scale.

(1) Calibration: BeVision S1 image particle analysis system can calibrate the real size of the particle accurately through the scale.

(2) Auto segmentation: split connected particles automatically.

(3) Insert the scale: insert the scale in a image, so the size of the particle can be observed directly.

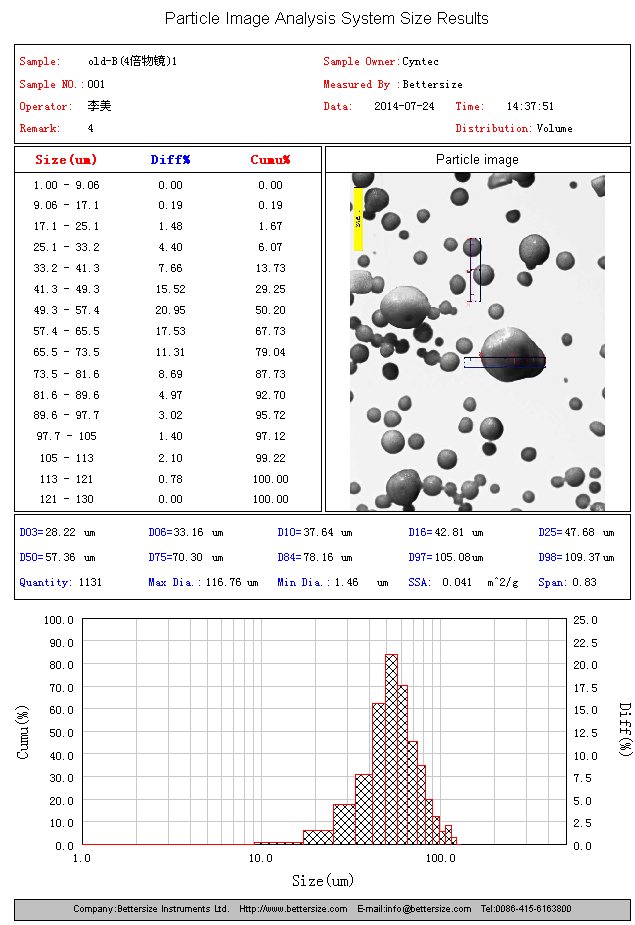

(4) Multiple analysis results: includes open image, save image, save result, query result, print particle size result, preview particle size result, print image, preview image, print L/D ratio result ,etc.

Example for report type

Specification

| Testing parameter | Material |

| Particle size distribution | Suspension, emusion, dry powder |

| General | BeVision S1 |

| Typical measurement time | Less than 10min |

| CCD | 5 Megapixel |

| Size | |

| Size range | 1-3000um |

| Accuracy | ≤3% (GBRM D50) |

| Repeatability | ≤3% (GBRM D50) |

| Magnification | Max.4000 times |

| System | |

| Voltage | 220VAC |

| Computer specification | |

| Computer interface | At least a USB2.0 port required |

| Opertion system | Windows XP, Windows 7,8 or 10 |

| Hardware specification | Intel Core I5, 4GB RAM, 250GB HD |